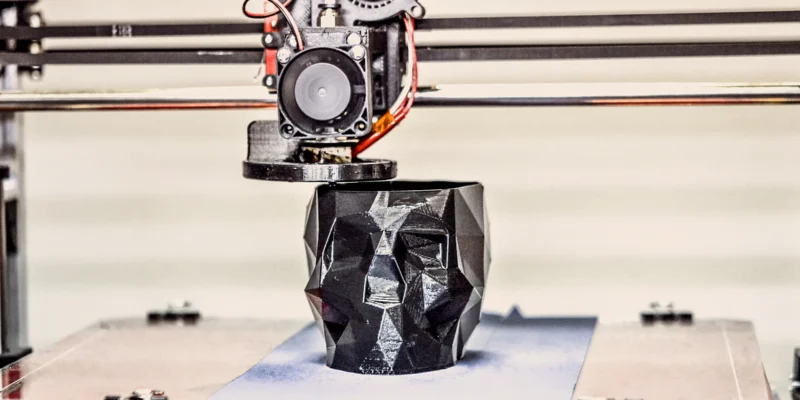

The development of new products typically involves multiple stages, from concept design to final production. One of the most critical stages is prototyping, where ideas take a tangible form, allowing designers and engineers to evaluate and refine their creations. Traditionally, prototyping was a time-consuming and expensive process, often requiring specialized tools and machinery. However, with the advent of commercial 3D printing services, this process has been revolutionized, offering unprecedented speed, flexibility, and cost-effectiveness.

Speed and Efficiency in Prototyping

Commercial 3D printing services have dramatically reduced the time required to produce prototypes. Traditional methods often involved creating molds or machining parts, which could take weeks or even months. In contrast, 3d printing services allows for rapid prototyping, with parts often produced within hours or days. This acceleration in the development process enables businesses to iterate quickly, testing multiple designs in a fraction of the time it would take using conventional methods.

This speed is particularly beneficial in industries where time-to-market is critical. For example, in the highly competitive consumer electronics sector, being the first to launch a new product can provide a significant advantage. By utilizing 3D printing for prototyping, companies can shorten their product development cycles, bringing innovative products to market faster than ever before.

Cost-Effective Solutions for Product Development

The cost savings associated with commercial 3D printing services are another significant advantage. Traditional prototyping methods often require costly tooling and machining, especially for complex or customized parts. 3D printing eliminates the need for these expensive tools, allowing businesses to produce prototypes at a fraction of the cost.

Moreover, because 3D printing is an additive process, material usage is optimized, further reducing costs. Instead of cutting away material from a larger block, as in subtractive manufacturing, 3D printing builds up the part layer by layer, using only the necessary amount of material. This efficiency not only lowers material costs but also minimizes waste, making the process more sustainable.

Flexibility and Customization

One of the most compelling aspects of commercial 3D printing services is the flexibility they offer in product development. Designers and engineers can experiment with complex geometries and intricate designs that would be difficult or impossible to achieve with traditional manufacturing techniques. This freedom allows for greater innovation and creativity, leading to the development of more advanced and sophisticated products.

In addition to flexibility in design, 3D printing also enables a high degree of customization. For industries like healthcare, where personalized solutions are often required, 3D printing can produce bespoke prosthetics, implants, and medical devices tailored to the unique needs of individual patients. This level of customization is not only valuable for improving patient outcomes but also provides businesses with a competitive edge in the market.

Conclusion

Commercial 3D printing services have revolutionized prototyping and product development, offering significant advantages in speed, cost, and flexibility. By enabling rapid iteration, reducing costs, and allowing for greater innovation, these services have become an essential tool for businesses looking to stay ahead in today’s fast-paced market. As 3D printing technology continues to advance, its role in product development is likely to expand, offering even more opportunities for businesses to innovate and succeed.